According to the service manual, the grain tank has to come off in order to pull the clean grain elevator. That’s a tall order. In my case, we are talking about the 25 bushel “Big Bin”. If it is anything like the 17 bushel version on the 60’s/early 66, getting the tank back on is even harder than taking off. So on this 66 I am repairing I thought I would try to take it off with the tank still on. Granted, the tank has to come off anyway, so I was not doing myself any favors, but thought this would be an educational experience.

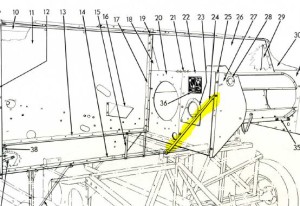

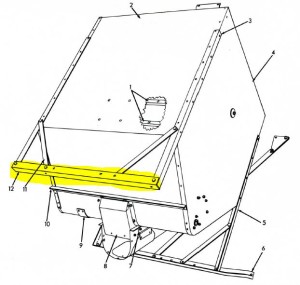

Sure enough, after detaching the elevator, there didn’t seem to be a way to pull it out. It then occurred to me that perhaps I could pull it out from underneath the combine. I took off the highlighted parts shown below, raised up the wheel under the tank and pulled it out from behind the combine.

One word of caution. When lifting the wheel, your left side front of the header will take a dive into the ground, so you may have to lift up the other wheel as well. I have a gravel floor so I was able to gain a couple inches clearance by digging into the floor so the header was not unduly stressed.

I posted for help with my 72 on YT and almost got threats for considering junking my recent purchase – I want to put it back to work, but I need help. The bottom end of my grain elevator crumbled when I opened the door.

From what I have read, this can be done without removing the grain tank. How high does the left wheel need to be off of the ground?

Once I get it out, do I have to dissemble lower end and then grind rivets out to refabricate lower end sides and backing?

Hi Dan,

Your talking about a model 72, I did it on a 66. Your mileage may vary on this method; let us know if you run into a problem.

For me, if I recall, I had the wheel up about 8 inches or so? I had the benefit of a loose pack floor so my elevator dug into the ground a bit when I pulled it out. So you may need to go a bit higher. Keep an eye out on the front left corner of the header as it will dig into the ground.(Or maybe not on a 72?) You may have to lift the other wheel up a little because of that. Its still a pain to remove but beats taking off the tank. Whatever you do…SAFTEY! Don’t bet your life on jacks. Block it up.

As for fixing your elevator, I never rebuilt one. Yeah I can imagine a lot of grinding and such. I do have the door if you need it. You may want to find a metal fab shop to do it if it is not your cup of tea.

Best Wishes

PS if you decide to scrap it, contact me. There are very precious parts on a 72 that we could use.

It’s already up on blocks, but I will take it higher and very safely. We will be talking about chains & paddles. Thanks

Let me know how it works out. Email me or call evenings if you have any questions..or just keep asking them here.

I got the lower end of the elevator off by drilling out 11 rivets and removing it from the tower. I will need a bunch of stuff, but I plan on getting everything loose and identifying all of the parts o be replaced before I begin the rebuild.

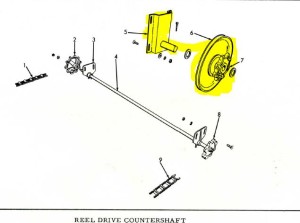

Question – please look at the pully configuration on the rear ends of these two 72’s. Notice the difference on the main power shaft ….. one pully is a lot larger.

the first is my configuration, and the second not. Do you have any idea why and which configuration I should use?

httphttps://www.youtube.com/watch?v=yw4addq7oxw

https://www.youtube.com/watch?v=T8vKkmH2BNk

thanks

Dan,

The smaller sheave is standard. Not aware of any factory deviation from that, (but doesn’t mean there wasn’t).